How do cogeneration systems work?

What are the different types of cogeneration?

There are different types of cogeneration, including:

Gas turbine powered: these systems use the waste heat in the flue gas of gas turbines to generate energy; typically they use natural gas as a source of fuel;

Gas engine powered: in this cogeneration process, a reciprocating gas engine is used. These types of CHP cogeneration plants are usually manufactured as fully packaged units that can be installed inside a dedicated plant room or in a dedicated external space and are easy to connect to the site’s heating and electric infrastructure;

Biofuel engine: these systems are very similar to the previous ones, in that they use a reciprocating gas or diesel engine adapted to using biofuel as a source of fuel. Using biofuels reduces fossil fuel consumption and leads to reduced carbon emissions. These plants also generally come in assembled units that are easy to plug into existing heating and power infrastructure;

Steam turbine CHP: this system uses the heating system as the steam condenser for the steam turbine.

Some cogeneration plants use biomass derived from industrial and municipal solid waste as fuel, and are therefore called biomass cogeneration systems.

What is meant by high-efficiency cogeneration?

The concept of “high-efficiency cogeneration” has been defined by the European Union with directive 2012/27/EU, which replaced previous Directive 2004/8 EC. According to the latest directive “‘high-efficiency cogeneration” high-efficiency cogeneration shall fulfil the following criteria:

Cogeneration production from cogeneration units shall provide primary energy savings calculated according to point (b) of at least 10 % compared with the references for separate production of heat and electricity;

Production from small-scale and micro-cogeneration units providing primary energy savings may qualify as high-efficiency cogeneration.

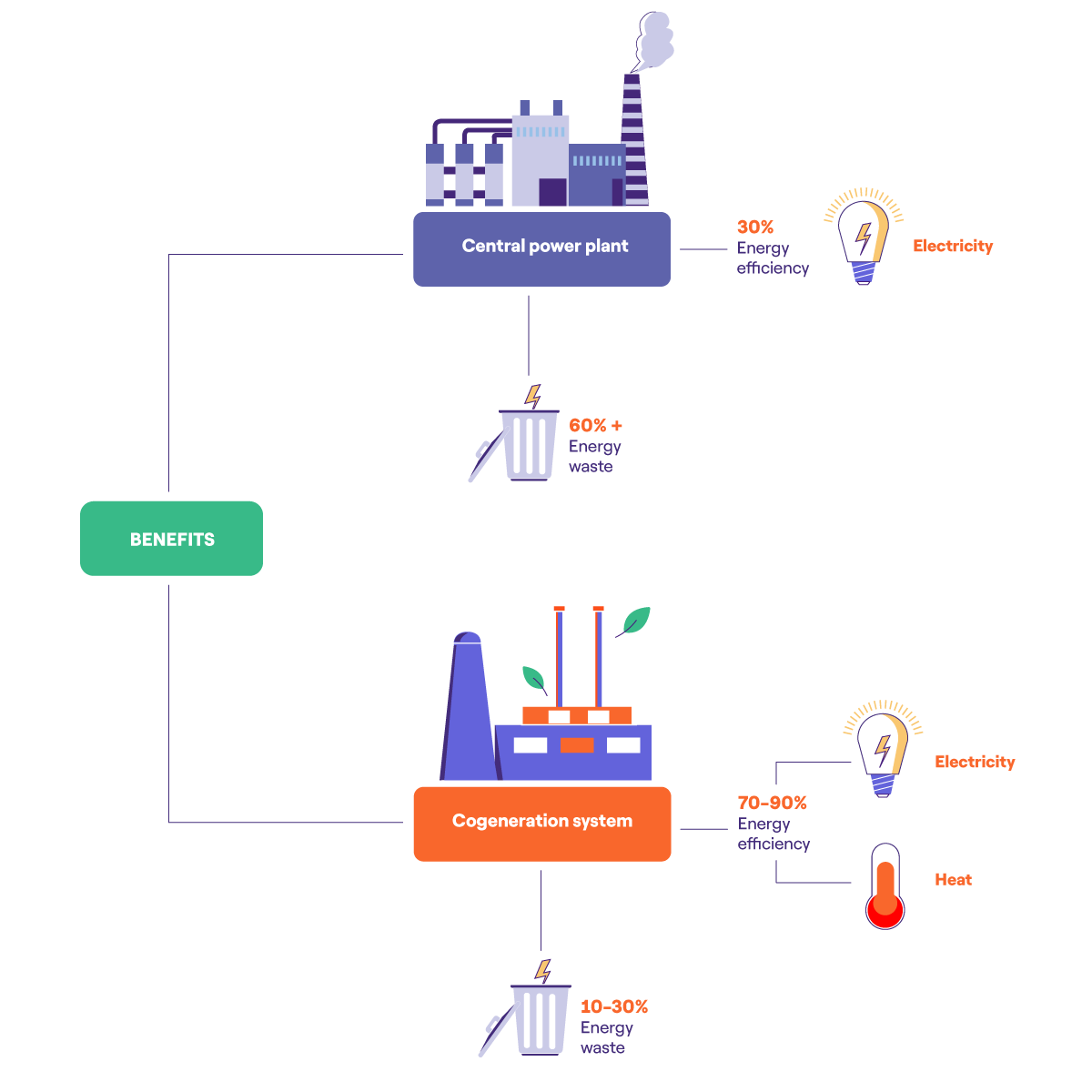

What are the benefits of cogeneration?

- Improve the overall efficiency of energy usage by combining the production of heat and electric energy in a single generator

- Reduce energy costs

- Lower emissions

- Reduce risks of power cuts due to grid problems

- Qualify for economic incentives relating to energy efficiency projects

- Use renewable energy sources like biomass

- Be adapted to fit the needs of all sorts of users, including residential

- Reduce reliance on energy grid, since a CHP is usually onsite or nearby

- Promote energy self sufficiency and reduce energy imports